Guitar string construction is a critical element of an instrument’s overall sound and playability. The strings are responsible for producing the tones that resonate through the body of the guitar, and their design has evolved over time to enhance musical expression and performance. These strings are typically made from a variety of materials such as nylon for classical guitars or metal alloys like nickel or bronze for acoustic and electric guitars. The construction process involves precise engineering to create strings that are not only melodious but also durable and responsive to touch.

When you look at different types of guitars, each string on the instrument can significantly influence its timbre and feel. For steel-string acoustic guitars or electric guitars, the construction includes a core wire with a tight winding of a secondary wire material, which affects both tension and tonal quality. How these strings are made and the materials used determine the guitar’s sound; String gauge is another factor, with lighter gauge strings typically produce brighter tones, while heavier ones give a richer, deeper sound. Understanding the basics of guitar string construction can help you make informed choices that suit your playing style and the genres of music you enjoy.

Materials & Composition

The different guitar string types & string materials profoundly influence the sound and playability of a guitar. Their construction from various materials affects tone, durability, and the tactile feel under your fingers.

Core Materials

Guitar string cores come in two primary shapes: round and hexagonal. Round core strings are known for their flexibility and a more mellow tone, which suits styles like blues and classic rock, and they offer a slight increase in sustain with a gentler attack.

Hex core strings, on the other hand, are more modern in their design and provide a brighter, louder, and crisper tone. They are also more stable and stay in tune better, which makes them a preferred choice for many players looking for a sharp and articulate sound. The choice between the two is largely a matter of personal preference and the musical style a player is aiming to achieve.

The cores of guitar strings are typically made from steel, which is favored for its strength and durability. Steel cores provide a bright and clear tone, which is particularly important for the higher-pitched strings. For acoustic guitars, some strings may use a nylon core, which produces a softer and warmer sound, often preferred for classical and flamenco music.

The steel core can also be plated with materials like nickel for smoother playability and a slightly warmer tone. In the case of bass guitar strings, some may have a core made of materials like silk to add flexibility and reduce finger noise. The choice of core material significantly influences the overall tone and feel of the strings, catering to different playing styles and preferences.

Winding Techniques

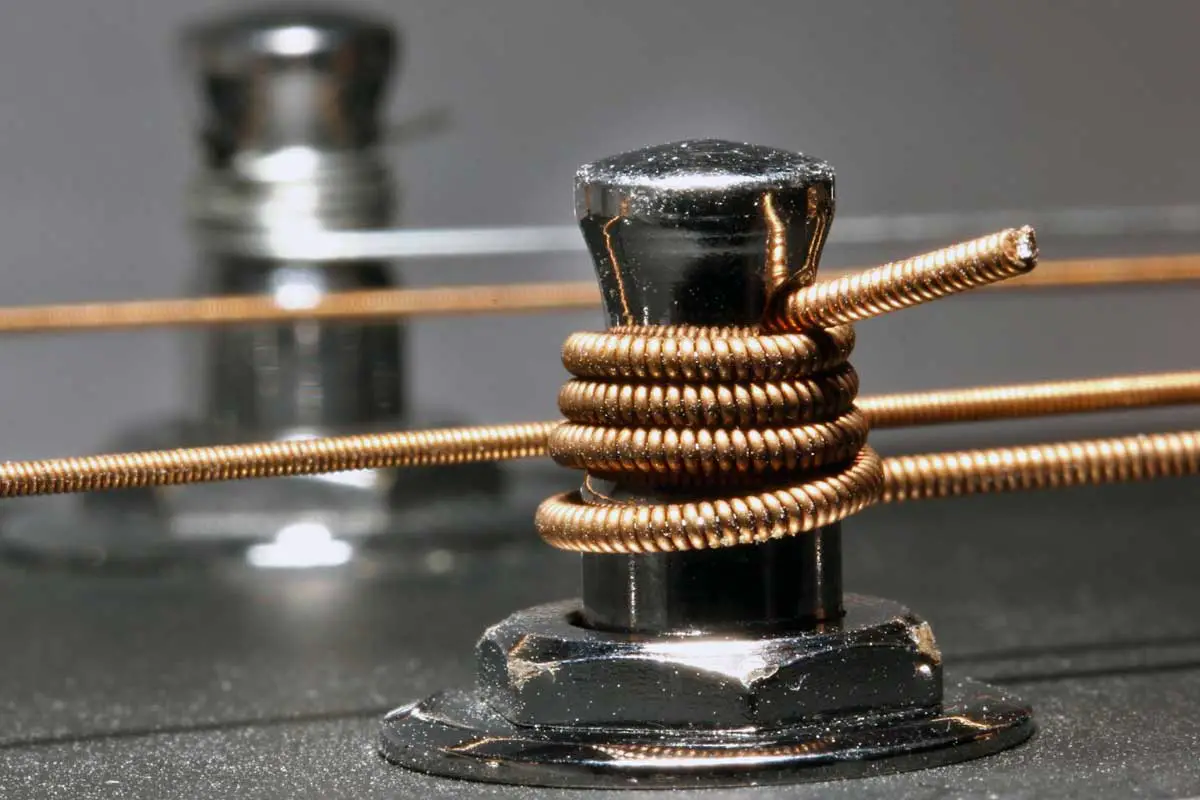

Guitar strings are commonly categorized by their winding techniques, which greatly affect their tone and playability. Roundwound strings, the most popular type, have a round wire wrapped around the core, giving them a bright and textured feel, as well as a crisp, clear sound that’s versatile for many styles.

Flatwound strings, on the other hand, use a flat ribbon wire for winding, resulting in a smooth surface that’s gentle on the fingers and frets, and they produce a darker, mellower tone favored in jazz and some vintage rock tones.

Halfwound strings (or groundwound) strike a middle ground between the two, with a round wire that’s partially flattened to reduce finger noise while still retaining some of the brightness of roundwound strings. Each winding technique offers distinct characteristics that cater to different playing styles and tonal preferences.

| Winding Type | Sound Characteristics | Common Genres |

|---|---|---|

| Roundwound | Bright, textured, clear | Rock, Blues, Metal, Pop |

| Flatwound | Darker, mellower, smooth | Jazz, R&B, some vintage Rock |

| Halfwound | Brighter than flatwound, less finger noise than roundwound | Jazz, Fusion, Pop, Rock |

Each winding type offers a unique tonal palette and may be chosen not only based on the genre but also based on personal preference and the specific sound you’re aiming to achieve.

Coatings & Treatments

String coatings and treatments are applied to guitar strings to extend their lifespan by protecting them from corrosion and dirt. A common type of coating is a thin layer of polymer, which acts as a barrier against elements that can degrade the string, such as oils, moisture, and skin acids.

The benefits of coated strings include longer string life, consistent tone, and reduced finger noise, which can be particularly advantageous for recording or performing artists who require a clean sound. However, coated strings often cost more than uncoated strings, and some players may notice a slight difference in feel or a subtle dampening of the string’s natural brightness.

Additionally, the tactile sensation and the tonal characteristics can be a matter of personal preference; some may prefer the ‘slick’ feel of coated strings, while others favor the traditional feel of uncoated strings. The importance of string coatings in guitar string construction lies in their ability to offer players a choice between longevity and cost, as well as the type of feel and sound they desire from their instrument.

How Guitar Strings Are Made

Modern guitar string manufacturing is a precise process that involves several steps to ensure quality and consistency. The process typically begins with the selection of materials, where high-carbon steel is commonly used for the core wire due to its strength and tonal properties.

This core wire is then drawn to the desired thickness through a series of dies in a process called wire drawing. Once the core reaches the specified gauge, it may be twisted into a hexagonal shape for better grip if hex core strings are being made.

Then comes the winding process, where either round, flat, or halfround wire is wound around the core wire to create the outer wrap of the string. This winding is done with meticulous precision to ensure even tension and a uniform surface.

Coated strings undergo an additional step where a protective polymer layer is applied. The strings are then cut to length, and ball ends are attached to one end of the string to secure it to the guitar bridge. Finally, the strings are packaged in corrosion-resistant envelopes to preserve their freshness until they are ready to be used.

Related: Elixer Nanoweb vs Polyweb

Here’s a simplified list of the manufacturing steps:

- Material selection (e.g., high-carbon steel for core)

- Wire drawing to create the core wire

- Core wire shaping (round or hexagonal)

- Winding with wrap wire (roundwound, flatwound, or halfwound)

- Application of coatings (for coated strings)

- Cutting to length and attaching ball ends

- Packaging in corrosion-resistant envelopes

String Gauges and Tension

Understanding the relationship between string gauges and tension is essential for guitar setup and playability. Selecting the appropriate gauge and tension influences both tone and feel.

Gauges and Guitar Types

Guitar types vary widely, and each requires different string gauges for optimal sound. Electric guitars often employ lighter gauges facilitating bending and vibrato, whereas acoustic guitars typically use medium to heavier gauges providing a fuller tone and volume. Classical guitars pair well with nylon strings which have different tension metrics compared to steel strings.

- Electric: Lighter gauges (0.008-0.046)

- Acoustic: Medium to heavier gauges (0.011-0.056)

- Classical: Varied tensions in nylon strings (Normal, Hard, Extra Hard)

The choice of gauge should reflect your playing style; lighter gauges are easier on the fingers and suit fast playing, while thicker strings offer richer, more resonant tones.

Tension and Playability

String tension has a direct impact on playability. High tension strings may provide more volume and a crisper sound but require more finger strength to fret and bend notes. Medium tension strings are balanced, making them a versatile choice for various styles, whereas low tension strings are gentler on the fingers, facilitating extended playing sessions with less fatigue.

- High tension: Brighter tone, higher volume, harder to play

- Medium tension: Balanced tone and playability

- Low tension: Softer tone, easier to play

Sound Characteristics

The construction of guitar strings plays a crucial role in shaping the sound characteristics of a guitar. From the materials used to the way they are wound, strings affect tone, sustain, and clarity.

Tone and Resonance

Tone is the quality of sound that distinguishes different types of sound production, such as the warm, bright, or dark sounds produced by guitar strings. The composition of your guitar strings, whether they’re made from nylon or steel, significantly impacts these qualities. For example, nylon strings tend to produce a warmer and mellower tone typical of classical guitars, while steel strings offer a brighter and more metallic sound found in acoustic and electric guitars.

Resonance, on the other hand, defines how the guitar’s body amplifies the vibrations from the strings, contributing to volume and fullness of your guitar’s output. A string’s gauge (thickness) influences how freely it vibrates, with thicker strings typically providing more resonance, leading to a richer sound.

Pitch and Harmonics

Pitch refers to the perceived frequency of a sound, and in the context of guitar strings, it’s primarily determined by string tension, mass, and length. When you tune your guitar, you are actually adjusting the tension of the strings to match specific frequencies for each note.

String construction also affects the harmonics, which are the multiple frequencies that resonate along with the fundamental note you play. The quality and composition of the string material can enhance or dampen these frequencies, thus affecting the clarity and responsiveness of the notes produced.